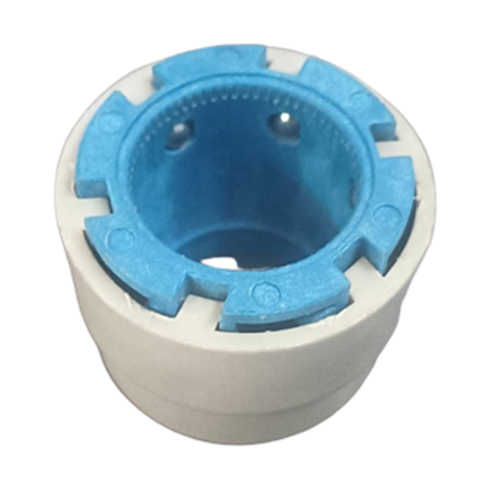

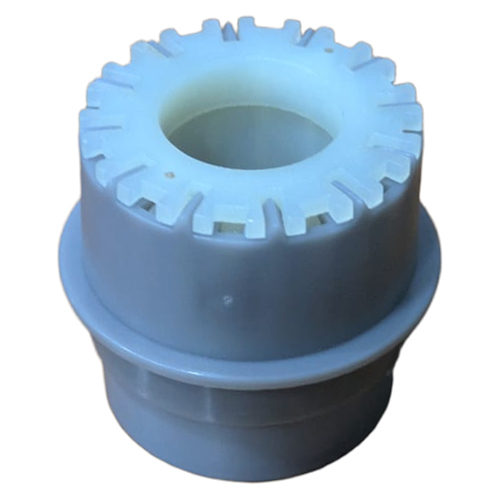

Zinser Spindle Cutter

Price 50.0 INR/ Number

Zinser Spindle Cutter Specification

- Features

- AUTO DOFFING CUTTER

- Size

- 35

- Capacity

- 5000 Pcs/hr

- Surface Finish

- FINISHING

- NO. Of Hole

- 1

- Product Type

- Textile Machinery Components

- Material

- Steel

- Textile Machine Type

- Spinning Machine

- Spare/Component Type

- Spindle

- Usage

- Industrial

- Speed

- 25000 RPM

- Dimension (L*W*H)

- 35 Millimeter (mm)

- Weight

- 10 Grams (g)

- Warranty

- NO

Zinser Spindle Cutter Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- Mundra Port

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- BOX PACKING OR WOODEN BOX

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Zinser Spindle Cutter

A Spindle Cutter is a mechanical or pneumatic blade system installed near each spindle to cut the yarn automatically during the doffing cycle (when full bobbins are removed and empty tubes are placed). It works as part of the auto doffer system in modern ring frames.

Purpose of the Spindle Cutter

Where is It Used?

Installed on:

LMW auto doffer machines (e.g., LF4200A)

Rieter machines with automatic doffing (G38, G37)

Zinser models with ROBOdoff system

Marzoli FT Series auto doffers

Components of a Spindle Cutter System

Working Process (Step-by-Step)

- Auto doffer is activated

- Machine sends signal to spindle brake spindle stops

- Spindle cutter engages pneumatic blade cuts yarn

- Doffer removes full bobbin

- Empty bobbin placed

- Yarn piecing process begins again

Advantages

Common Issues & Maintenance

Compatible Machine Examples

Suppliers & Manufacturers

Precision-Engineered for Industrial Spinning Machines

Our Zinser Spindle Cutter is meticulously engineered for integration with spinning machines, ensuring optimal performance in demanding industrial environments. With dimensions of 35 mm and a lightweight profile, this spindle cutter facilitates smoother textile processing, reduces downtime, and keeps your machinery running at peak efficiency.

High-Speed, High-Capacity Performance

Operating at speeds up to 25,000 RPM and a capacity of 5,000 pieces per hour, the Zinser Spindle Cutter delivers exceptional throughput. Its robust steel construction and superior finishing ensure long-term reliability, making it an essential component for textile manufacturers aiming for high productivity without sacrificing product quality.

FAQs of Zinser Spindle Cutter:

Q: How does the Zinser Spindle Cutter enhance the efficiency of spinning machines?

A: The Zinser Spindle Cutter is designed with an AUTO DOFFING feature that streamlines the yarn cutting process, reducing manual intervention and downtime. Its high-speed operation of up to 25,000 RPM boosts the overall productivity of spinning machines in industrial settings.Q: What materials are used in the manufacture of the Zinser Spindle Cutter?

A: This spindle cutter is constructed from high-quality steel and features a precision surface finish, ensuring durability and resistance to wear during rapid, continuous use in textile production.Q: When should the Zinser Spindle Cutter be replaced?

A: Replacement is generally recommended when performance declines or visible wear and tear is noticed. Because there is no warranty, regular inspection as part of your maintenance process is advisable to avoid unexpected downtimes.Q: Where can the Zinser Spindle Cutter be used?

A: This component is suitable for use in industrial spinning machines, particularly in textile manufacturing plants focused on high-volume yarn production.Q: What is the installation process for the Zinser Spindle Cutter?

A: The single-hole design with a 35 mm dimension makes installation straightforward for technicians familiar with spinning machine maintenance. Always ensure the machine is powered off and follow the manufacturers installation guidelines for safety.Q: Why choose the Zinser Spindle Cutter for your spinning machinery?

A: Its high processing capacity, robust material, and auto doffing feature make it an effective solution for minimizing downtime and maximizing output, making it a smart investment for textile companies aiming for efficient and reliable operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spindle Cutter Category

LMW Spindle Cutter

Price 50.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

NO. Of Hole : 1

Weight : 50 Grams (g)

Hardness : Rockwell

Rieter Spindle Cutter

Price 120.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

NO. Of Hole : 1

Weight : 50 Grams (g)

Hardness : Rockwell

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry