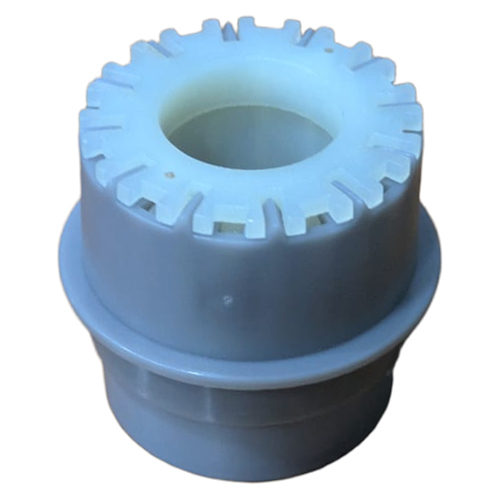

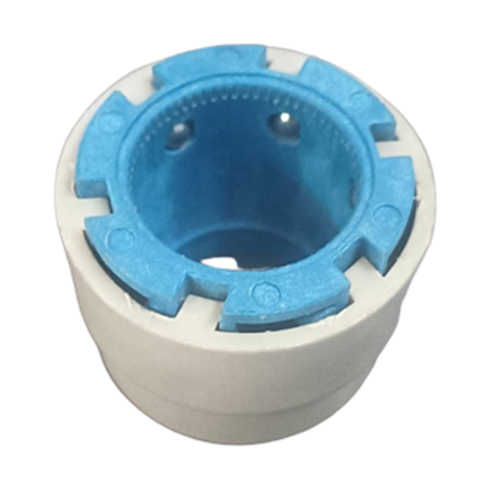

LMW Spindle Cutter

Price 50.0 INR/ Piece

LMW Spindle Cutter Specification

- Hardness

- Rockwell

- Part Type

- PLASTIC CUTTER

- Automation Grade

- AUTO DOFFING CUTTER FOR LMW MACHINE

- Noise Level

- 75 db

- Features

- AUTO DOFFING

- Surface Finish

- FINISHING PLASTIC

- Diameter

- 22 Millimeter (mm)

- NO. Of Hole

- 1

- Capacity

- 500 Pcs/hr

- Size

- 20MM DUI

- Product Type

- Textile Machinery Components

- Material

- Plastic

- Textile Machine Type

- Spinning Machine

- Spare/Component Type

- Spindle

- Usage

- Industrial

- Speed

- 25000 RPM

- Dimension (L*W*H)

- 22 Millimeter (mm)

- Weight

- 50 Grams (g)

- Warranty

- 1

LMW Spindle Cutter Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- Mundra Port

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 45 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- BOX PACKING OR WOODEN BOX

- Main Export Market(s)

- Australia, Middle East, Africa, Asia, North America, South America, Western Europe, Central America, Eastern Europe

- Main Domestic Market

- North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Sikkim, Tamil Nadu, Telangana, Uttarakhand, West Bengal, All India, South India, Jharkhand, Assam, Delhi, Dadra and Nagar Haveli, Arunachal Pradesh, Chhattisgarh, Pondicherry, Uttar Pradesh, Central India, West India, Bihar, Chandigarh, Daman and Diu, Goa, Andaman and Nicobar Islands, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Tripura

About LMW Spindle Cutter

A Spindle Cutter is a mechanical or pneumatic blade system installed near each spindle to cut the yarn automatically during the doffing cycle (when full bobbins are removed and empty tubes are placed). It works as part of the auto doffer system in modern ring frames.

Purpose of the Spindle Cutter

Where is It Used?

Installed on:

-

LMW auto doffer machines (e.g., LF4200A)

-

Rieter machines with automatic doffing (G38, G37)

-

Zinser models with ROBOdoff system

-

Marzoli FT Series auto doffers

Components of a Spindle Cutter System

Working Process (Step-by-Step)

- Auto doffer is activated

- Machine sends signal to spindle brake spindle stops

- Spindle cutter engages pneumatic blade cuts yarn

- Doffer removes full bobbin

- Empty bobbin placed

- Yarn piecing process begins again

Advantages

Common Issues & Maintenance

Compatible Machine Examples

Suppliers & Manufacturers

Precision Cutting for Spinning Machines

The LMW Spindle Cutter is engineered to ensure smooth, reliable cuts in modern spinning machines, making it indispensable for textile production lines. Its automatic doffing capability improves efficiency and keeps downtime to a minimum, supporting a stable workflow. Designed with industrial conditions in mind, its robust plastic build and compliance with Rockwell hardness standards ensure both longevity and performance, even in demanding mill environments.

Enhanced Durability and Ease of Replacement

With a streamlined design and a surface finished to precise plastic standards, the spindle cutter maintains high performance throughout its lifespan. At just 50 grams, its lightweight and easy to handle, which simplifies the replacement process and keeps your machinery running smoothly. The components resilience is backed by a one-year warranty, giving users confidence in both functionality and durability.

FAQs of LMW Spindle Cutter:

Q: How is the LMW Spindle Cutter installed on a spinning machine?

A: The LMW Spindle Cutter is specifically designed for quick and straightforward installation onto spinning machines, particularly those compatible with the 20MM DUI size. Simply align the spindle cutter with the spindle assembly and secure it according to your manufacturers guidelines, ensuring proper orientation and tightness for optimal cutting performance.Q: What is the main benefit of using the auto doffing feature?

A: The auto doffing feature enables the spindle cutter to automatically remove processed material from the spindle, significantly reducing manual intervention. This leads to increased efficiency, less downtime, and supports higher throughput, especially in continuous textile manufacturing operations.Q: When should I consider replacing my spindle cutter?

A: Replacement is recommended when you notice a decline in cutting efficiency, increased wear, or if the cutters surface has become damaged. Regular maintenance checks should be conducted based on usage, but typically, you should expect reliable operation within its warranty period, assuming average industrial use.Q: Where is this spindle cutter manufactured and supplied from?

A: This spindle cutter is manufactured, exported, and supplied from India, catering to both domestic and international textile machinery markets.Q: What is the typical process for using this cutter in textile production?

A: Once installed, the cutter operates automatically with the spinning machines mechanism, performing precise cutting tasks at high RPM and leveraging the auto doffing feature. It can process up to 500 pieces per hour without manual input, making it ideal for batch or continuous textile manufacturing.Q: Is this spindle cutter compatible with all spinning machines?

A: This cutter is specifically engineered for LMW spinning machines that use 20MM DUI spindles and a 22mm diameter. Confirm your machines specifications to ensure compatibility, or consult with the supplier for guidance regarding integration with other machine models.Q: What are the advantages of the plastic material and surface finish?

A: Using durable plastic ensures a lightweight cutter that minimizes wear on machine components and maintains cutting precision. The finished surface enhances smooth operation and reduces the risk of fiber buildup, assuring consistent quality in textile cutting applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spindle Cutter Category

Zinser Spindle Cutter

Price 50.0 INR / Number

Minimum Order Quantity : 100 Pieces

Warranty : NO

NO. Of Hole : 1

Product Type : Textile Machinery Components

Material : Steel

Rieter Spindle Cutter

Price 120.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Warranty : 1

NO. Of Hole : 1

Product Type : Textile Machinery Components

Material : Plastic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry