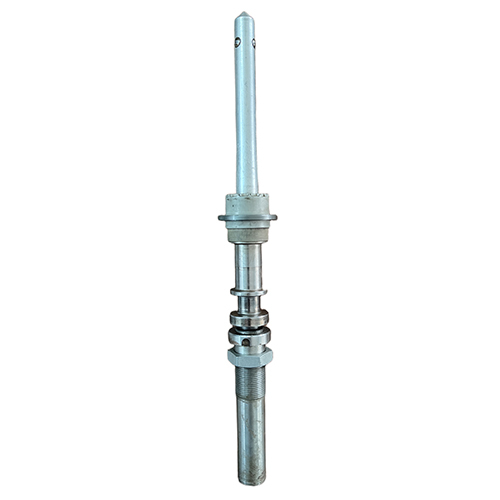

Zinser Ring Frame Spindle Bolster

Price 1200.0 INR/ Piece

Zinser Ring Frame Spindle Bolster Specification

- Diameter

- 28 Millimeter (mm)

- Noise Level

- 75 db

- Features

- RING FRAME SPINDLE

- Surface Finish

- POLISHING

- Size

- 160MM TO 210MM

- Thread Type

- 25MM X 1.5MM

- Capacity

- 1000 Kg/day

- Product Type

- Textile Machinery Components

- Material

- Aluminum

- Textile Machine Type

- Spinning Machine

- Spare/Component Type

- Spindle

- Usage

- Industrial

- Speed

- 25000 RPM

- Weight

- 400 Grams (g)

- Warranty

- 1

Zinser Ring Frame Spindle Bolster Trade Information

- Minimum Order Quantity

- 100 Sets

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cash Against Delivery (CAD)

- Supply Ability

- 7000 Sets Per Month

- Delivery Time

- 45 Days

- Sample Available

- No

- Main Export Market(s)

- Asia, Central America, North America, South America, Eastern Europe, Western Europe, Australia, Middle East, Africa

- Main Domestic Market

- All India

About Zinser Ring Frame Spindle Bolster

Products Spindles: HF-1, HF-21, HF-100, CS1, CS 21 insert

For Machine: Reiter, L.R (LMW) LR6, LR8, LR9, LR7 machines, Texaco, KTTM, MMC, Marzoli, Zinser, Textool, suessen.

For Process Type: cotton industries, man-made fibers, wool, and blends

Product Description

- Material : spindle blade : EN 31 alloy (bearing steel), aluminum plug : LM 6, wharves : EN 24 alloy

- Spindles wharves diameter 18.5 to 22 mm.

- high quality , low vibration, Operating long life

- Supplies complete set with flange, nut, and spindle lock.

- manufacture spindle for ring diameter : 38mm , 40mm , 42mm, 45mm, 48mm etc

- We supplied spindle with specified insert as, Vindex industries.

Spindle Application

- Vindex Industries can reduce the weight of spindle top part (new design )

- Vindex Industries reduce vibration up to 0.05 mm/sec.

- Recommended for longer tube (165 to 250mm)

- Vindex reduce noise level to 75 DBA

- Suitable for any make ring spinning machine

- For longer high precision Operating.

- Short delivery time

Advantages

- Low noise & Power

- High speed up-to 25,000 rpm.

- Dynamically balanced.

- Each Stage Quality Checks to ensure exquisite quality system maintenance for superior performance.

- Long lubricating cycle

Precision Engineering for Superior Yarn Production

Engineered with meticulous attention, the Zinser Ring Frame Spindle Bolster delivers consistent performance in high-speed spinning applications. Its precision-polished surface and robust thread type (25MM X 1.5MM) minimize friction and wear, ensuring stable spinning conditions and greater yarn quality for textile producers.

Enhance Operational Efficiency

With a capacity of 1,000 kg per day and a lightweight design (400 grams), this spindle bolster significantly boosts productivity. Its compatibility with various spindle sizes and spinning machines makes it a versatile component, tailored to meet the evolving demands of modern textile operations across India.

FAQs of Zinser Ring Frame Spindle Bolster:

Q: How do I install the Zinser Ring Frame Spindle Bolster in my spinning machine?

A: Installation requires aligning the bolsters diameter (28mm) with the corresponding spindle size (160mm to 210mm) and securing it using the specified thread type (25MM X 1.5MM). Ensure the polished aluminum surface is clean before fitting for optimal performance. Professional assistance is recommended during installation for accurate results.Q: What are the main benefits of using this spindle bolster in textile spinning machines?

A: The primary benefits include reduced operational noise (75 db), high-speed compatibility (up to 25,000 RPM), and a significant daily capacity (1,000 kg). Its polished finish ensures minimal friction, while the aluminum material provides both strength and lightweight handling, contributing to improved machine durability and yarn quality.Q: When should the spindle bolster typically be replaced?

A: Replacement is recommended upon visible wear, decreased spinning efficiency, or after the one-year warranty period. Regular maintenance checks can help detect signs of fatigue early, ensuring uninterrupted machine operation and yarn integrity.Q: Where can I source the Zinser Ring Frame Spindle Bolster?

A: This product is available through textile machinery exporters, manufacturers, and suppliers throughout India. It is commonly sourced by industrial spinning mills seeking quality spare parts for their ring frame machines.Q: What process is involved in maintaining the spindle bolster for optimal performance?

A: Routine maintenance involves regular cleaning of the polished surface, periodic inspection for wear and tear, and lubricating as per manufacturer guidelines. Prompt replacement of worn-out components ensures consistent performance and prolongs the overall life of the spindle assembly.Q: How does the bolsters low noise level benefit industrial usage?

A: A noise level of 75 db minimizes operational disturbances, promoting a safer, more comfortable working environment. This reduction in noise helps textile facilities meet industry standards for workplace safety and enhances overall employee productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Spindle For Ring Spinning Machine Category

Marzoli Ring Frame Spindle Bolster

Price 1200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Textile Machine Type : Spinning Machine

Surface Finish : POLISHING

Spare/Component Type : Spindle

Size : 18.5 to 22 mm

Rieter Ring Frame Spindle Bolster

Price 1000.0 INR / Set

Minimum Order Quantity : 100 Sets

Textile Machine Type : Spinning Machine

Surface Finish : POLISHING

Spare/Component Type : Spindle

Size : 160MM TO 210MM

LMW Ring Frame Spindle Bolster

Price 1050.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Textile Machine Type : Spinning Machine

Surface Finish : POLISHING

Spare/Component Type : Spindle

Size : 160 to 250mm

KTTM Ring Frame Spindle Bolster

Price 800.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Textile Machine Type : Spinning Machine

Surface Finish : POLISHING

Spare/Component Type : Spindle

Size : 65 to 250mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry