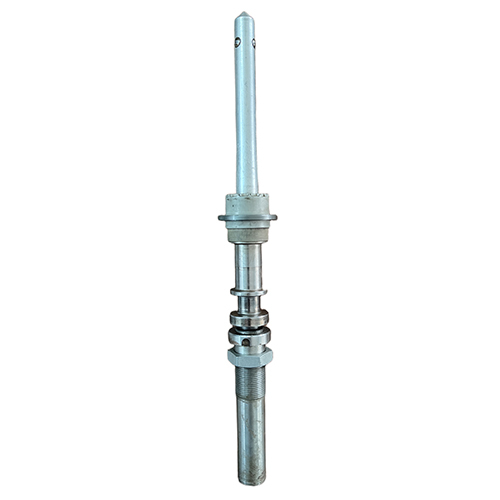

China Ring Frame Spindle Bolster

Price 600.0 INR/ Piece

China Ring Frame Spindle Bolster Specification

- Surface Finish

- POLISHING

- Features

- RUST FREE

- Size

- 160MM TO 250MM

- Capacity

- 120000 Tons/year

- Diameter

- 40 Millimeter (mm)

- NO. Of Hole

- 1

- Noise Level

- 75 db

- Thread Type

- 25

- Product Type

- Textile Machinery Components

- Material

- Steel

- Textile Machine Type

- Spinning Machine

- Spare/Component Type

- Spindle

- Usage

- Industrial

- Speed

- 25000 RPM

- Weight

- 400 GSM (gm/2)

- Warranty

- 1

China Ring Frame Spindle Bolster Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 7000 Pieces Per Month

- Delivery Time

- 45 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, North America, South America, Eastern Europe, Western Europe, Australia, Central America, Middle East, Africa

- Main Domestic Market

- All India

About China Ring Frame Spindle Bolster

Products Spindles: HF-1, HF-21, HF-100, CS1, CS 21 insert

For Machine: Reiter, L.R (LMW) LR6, LR8, LR9, LR7 machines, Texaco, KTTM, MMC, Marzoli, Zinser, Textool, suessen ,

For Process Type: cotton industries, man-made fibers, wool, and blends

Product Description

- Material : spindle blade : EN 31 alloy (bearing steel), aluminum plug : LM 6, wharves : EN 24 alloy

- Spindle€˜s wharves diameter 18.5 to 22 mm.

- high quality , low vibration, Operating long life

- Supplies complete set with flange, nut, and spindle lock.

- manufacture spindle for ring diameter : 38mm , 40mm , 42mm, 45mm, 48mm etc

- We supplied spindle with specified insert as, Vindex industries.

Spindle Application

- Vindex Industries can reduce the weight of spindle top part (new design )

- Vindex Industries reduce vibration up to 0.05 mm/sec.

- Recommended for longer tube (165 to 250mm)

- Vindex reduce noise level to 75 DBA

- Suitable for any make ring spinning machine

- For longer high precision Operating.

- Short delivery time

Advantages

- Low noise & Power

- High speed up-to 25,000 rpm.

- Dynamically balanced.

- Each Stage Quality Checks to ensure exquisite quality system maintenance for superior performance.

- Long lubricating cycle

Superior Surface Finish & Rust-Free Durability

The polished surface finish of our spindle bolster not only improves aesthetic appeal but also ensures corrosion resistance, maintaining quality over extended periods. Its rust-free steel construction withstands frequent industrial use, offering low maintenance and consistent performance, which is essential for textile manufacturing environments where reliability and longevity matter most.

Optimized for High-Speed Spinning Machines

Engineered to operate flawlessly at speeds up to 25,000 RPM with minimal noise (75 db), this spindle bolster guarantees smooth, vibration-free performance. Its precision design enables textile mills to maximize productivity while maintaining fabric integrity. Operators can rely on its robust construction for continuous processing in high-volume settings, supported by its weight specification of 400 GSM.

FAQs of China Ring Frame Spindle Bolster:

Q: How does the polished surface finish benefit the China Ring Frame Spindle Bolster?

A: The polished surface finish enhances the spindle bolsters resistance to rust, extends its lifespan, and improves its overall appearance, making it ideal for high-demand textile spinning environments where both durability and hygiene are critical.Q: What textile machine types is this spindle bolster suitable for?

A: This spindle bolster is specifically designed for spinning machines, ensuring compatibility with advanced industrial textile equipment used in fiber production and yarn spinning processes.Q: When should the spindle bolster be replaced or serviced?

A: Regular maintenance is advised during scheduled machine servicing, or sooner if there are signs of excessive noise, vibration, or surface damage. The product comes with a one-year warranty to assure performance during its initial period of use.Q: Where can this China Ring Frame Spindle Bolster be used?

A: It is widely used in industrial textile mills and spinning factories, especially where high-speed and high-capacity fiber processing is required. As an exporter, manufacturer, and supplier from India, we provide these components globally.Q: What is the process for installing the spindle bolster in spinning machines?

A: Installation requires aligning the bolster with the spindle assembly, securing it through its single hole design, and ensuring proper threading. Qualified operators or technicians should conduct installation for optimal safety and performance.Q: What are the main benefits of using this spindle bolster in textile production?

A: Key benefits include enhanced machine longevity due to rust-free steel, improved spinning efficiency at up to 25,000 RPM, reduced operational noise, and high production capacity supporting up to 120,000 tons annually.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Spindle For Ring Spinning Machine Category

Marzoli Ring Frame Spindle Bolster

Price 1200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Surface Finish : POLISHING

Size : 18.5 to 22 mm

Diameter : 40 Millimeter (mm)

Rieter Ring Frame Spindle Bolster

Price 1000.0 INR / Set

Minimum Order Quantity : 100 Sets

Usage : Industrial

Surface Finish : POLISHING

Size : 160MM TO 210MM

Diameter : 32 Millimeter (mm)

LMW Ring Frame Spindle Bolster

Price 1050.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Surface Finish : POLISHING

Size : 160 to 250mm

Diameter : 38 Millimeter (mm)

KTTM Ring Frame Spindle Bolster

Price 800.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Surface Finish : POLISHING

Size : 65 to 250mm

Diameter : 38 Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry